Our achievements

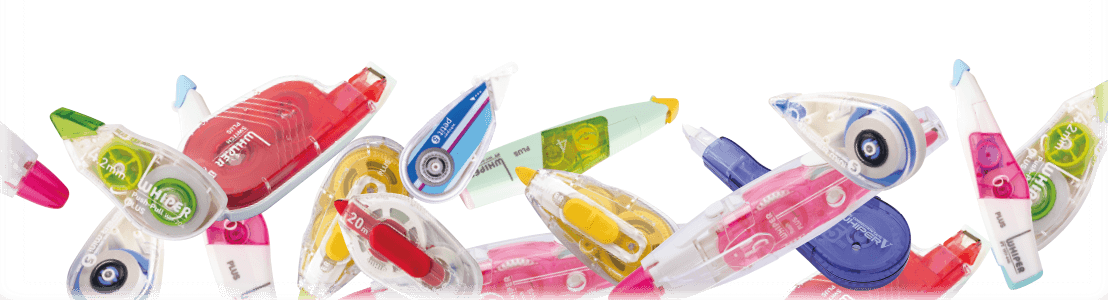

Tape product (in conversion of length of tapes)

Earth & Moon round-trip production volume

Earth & Moon round-trip production volume

In 1995, we started our factory with 15 employees; now we have grown to become one of the largest stationery production factories with around 2,500 staff. Our products have received great feedback from countries around the world, in America, Europe, and Asian countries. We have achieved this through co-operation and a strong work ethic within the company. Our administration department, quality control department, kaizen department, production system department and development department all work together to maintain a positive attitude and build a world-class business.

Human resources

Enthusiastic employees lead the way forwards

In the workplace, our staffs are in constant communication with each other, building strong working relationships. We also give our staff opportunities to improve their creativity and skills to meet new challenges. We aim to create an ideal workplace by assigning staff to the positions where they will be the most effective. Staffs who have been trained by this way will keep our company moving into the future.

Quality

Quality control in the factory

We apply Japanese quality standards consistently from factory to customer. Inspections, defect detection, and investigation of the causes of any problems are tightly controlled by the QC team. Customer satisfaction with our quality control and safety standards are essential. We analyze complaints and design solutions to prevent risk in any situation. As a result, only 1 out of our last 5 million products has received a complaint.

Improvement

Our aspiration "We will be better than now"

There is a self-conscious spirit of improvement in our factory. We work together to discuss and resolve any problem in an environment where the ideas of all are respected and recognized. In this open environment, every individual feels valued and listened to, making solutions easy to design and creating a positive and forward-looking workplace. The experience gained through these problem-solving processes stand us in good stead on the world market.

Production System

Production system by our staff

We absolutely understand that the effort our staffs make is the heart of our production system. By testing our systems with support from all staff, we have improved the efficiency of our production without compromising on quality. This staff-centered method helps all employees to clearly define their purpose and ambitionand allows our business to constantly improve. This production system brings many benefits: reduction in man-hours and an end to the burden of wasted time on staff, clarification of management and production procedures, and early detection of any possible issues..

Automatic machine development

Knowing the factory and developing automatic machine systems

The factory automation department and factory workers of each other department are working together to develop their automatic production system. We listen to ideas from all employees and quickly grasp and solve problems. The automation of our machinery system is reducing labor and other costs and contributing to increased productivity. Researching and providing solutions to new technical issues not only improves the production environment, but also an opportunity to train workers in new skills and accumulate knowledge and technology for the future generations of PLUS.